Tire Truing Guide

As technology evolved throughout the years, so did every industry, and the tire one is no different. Tires have come a long way since their introduction well over a century ago. They started out as leather bands around wooden wheels, and today we have tires capable of going over 200 mph.

Today, we consider tires perfect, mainly because we haven’t seen anything better. In comparison, older tires from a few decades ago seem like relics with countless defects, which isn’t too far from the truth. Modern tires are perfectly round pieces of rubber, but that wasn’t always the case. So, what is the solution to an imperfect tire? Truing.

Many of you may not have heard of this, which is why I’m covering this guide. I’ll explain what the process is, why it was used back then, and why there are situations where you may need to use it again.

What is Tire Truing?

Tire truing is a process often referred to as tire shaving, and it’s exactly what you may think it is. Truing is the process of shaving off the tread from a tire with a certain goal. It seems counterproductive, but there were times when truing was necessary. With that said, there are also some situations where you’ll need to use it even today.

Truing was popular and necessary in times when the tire manufacturing process wasn’t as precise as it is today. Tires came out from the factory with the general shape they should have but had many defects. Mounting a tire like that meant that you’d have vibrations and uneven wear in most situations. The solution to this was shaving the tires.

Manufacturers were aware of the problem, which is why the tires had more tread on them. This ensured that despite the shaving, you’d still have a tire with a deep enough tread to give you all the performance you need. A technician puts the tire on a machine and shaves it until it’s perfect enough to eliminate vibrations and get the best possible performance.

How are Tires Shaved?

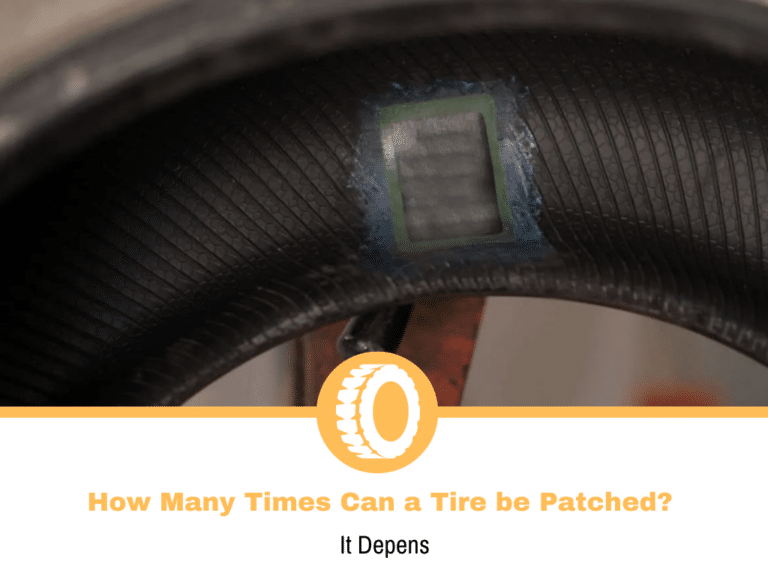

In the early days, tire shops had to shave the tires before they mounted them on the car. The process starts by mounting the tire on a rotating hub that spins it. A sharp blade is used for the process, and the technician slowly moves it toward the rotating tire. As the tire spins, the blade shaves off the parts of the tire that are uneven and gets it to a point where it’s as round as possible.

Considering that the process was necessary in an era where technology wasn’t as advanced as today, technicians didn’t have any fancy equipment to measure how perfect their job was. This meant they had to eyeball the process and hope they got the tire right. Some of the older generations talk about this process as a lost art because the human touch was crucial to getting the shape as perfect as possible. You could go to two different tire shops and get drastically different results. This is similar to the process of tuning the engine timing by ear on older cars.

There are situations where tire truing needs to be done on an existing tire. This is a situation where you have flat spots or uneven wear. In most cases, this goes unnoticed unless it’s a more serious matter to the point where you start to notice some vibrations. The process is the same here, but before the technician shaves the tires, he must first clear the debris stuck in the tire. In some situations, he may need to shave off a small part of the entire tread to get the tire to the point where it should be.

Tire Truing Today

Tire shaving was a common practice by around the 60s or 70s. At that point, manufacturers began making “perfect” tires, so the need for truing started to decline. Naturally, some shops continued doing it, and you can still find some to this day. The question here is, why is truing needed if the tires are perfect? There are several reasons, so let’s discuss each one.

The most common situation where people may want to shave a tire is with AWD cars. These kinds of cars operate optimally if the grip and traction levels on all 4 corners are identical. Imagine a situation where you have tires with about 20 thousand miles on them and still have plenty of tread. Unexpected things happen, and one of the tires may have some sidewall damage that cannot be fixed. You can get a new tire for that corner, but you’ll have an issue.

Due to how an AWD system works, there will be differences in the traction levels meaning that you’ll be putting unnecessary strain on the rest of the components. One option is to replace all 4 tires to combat the issue, but that solution is quite costly. This is where tire truing comes into play because it’s a more cost-effective solution. You can get only one tire, preferably the same model as the other 3, and take it to a shop for shaving. The technician will aim to shave off the tread and leave it with the same as the other 3. This will ensure you get the same performance on all 4 corners, and the AWD system will be happy and unstrained.

To be fair, shaving down a new tire is something you can do on a car with front or rear-wheel drive. Balance is critical, so keeping the performance similar in each corner is crucial.

Another common situation for tire truing is in some racing series, usually the budget ones. Nascar, Formula 1, and other popular sports rely on racing slicks, but there are some series where the rule mandates having racing tires that are barely road legal. I spoke about the legality of tires in my guide about driving slicks on the road, and the main thing was that road tires need to have grooves. The grooves are fine on a wet track, but they reduce the grip and traction levels noticeably in dry conditions. In these situations, you’d want to get the most out of the tires, which is where truing comes into play.

You can take these kinds of tires to a shop that shaves tires and turn them practically into semi-slicks. You’d still have some groves left, but most of them will be gone. This is ideal in dry situations because the contact patch increases, meaning you’d get higher top speed, and you can throw the car into a corner faster. Considering the use, the amount of shaving depends on your preference.

Most tires start with 8/32 of an inch, and a common practice is aiming for half of that. This gives you acceptable longevity on the track without some massive compromises. You can take it up a notch and go for the legal minimum, which may cost you longevity, but you’ll increase the performance gains. In this regard, it all comes down to your preference and balancing things between performance gains and how long you want the tires to last.

Previously I mentioned uneven wear and flat spots as reasons for getting your tires shaved. In most situations, it’s not a problem, and you’ll have to live with that, knowing that the tire may not last as long as it should. With that said, there are some extreme situations where edges may form around the flat spot, which can cause excessive vibrations. In this situation, tire shaving is a good way to smooth out the edges and make them as round as possible, thus eliminating the vibrations.

Finally, let’s talk about some rare instances with specialized off-road tires. Most of the models you’ll get at your local tire shop will be fine, and you can use them on the highway without worrying about the shape and vibrations. With that said, there are some situations where despite the best efforts, a specialized off-road tire won’t be as smooth on paved surfaces as it should be. People revert to shaving in these situations, especially if they intend to use it on a smooth surface. The defects won’t make a massive difference if they’re going strictly off-roading.

Is it Safe to Shave Tires?

Considering that the process is mechanical and the human factor plays a crucial role, we can call it safe, but not always. Some people and technicians have been shaving tires for decades, and they know what they’re doing, so shops with a proven record of this procedure are the best way to go.

If done correctly, tire shaving is a safe process, as long as you know you have a slight drawback. You’re removing part of the tread, so the longevity won’t be the same as before the truing.

Now let’s talk about the risk factor here. Shaving is a process where you’re technically removing part of the tread, and considering the human factor involved, you’ll need to be mindful of the consequences. Many things can go wrong, and you may end up with a permanently damaged tire. There aren’t too many people or shops that do this, but if you need to shave your tires, make sure to take it to a true professional.

Conclusion

Tire truing is a process we don’t see too often today. It was necessary in an era where the tire manufacturing process wasn’t as good as the one we have today, so the tires weren’t always perfect. Even though the need for shaving tires today is almost gone, there are still situations where you may consider it.

Despite the drop in interest, there are still a handful of situations where you may need to shave your tires. To ensure that you’re getting the best service possible, go to a shop or person that has been doing it for a long time. That way, you avoid the risk of additional damage.