Cost to Get a Tire Patched

Getting a tire patched is the cheapest go-to solution when one encounters a punctured tire. In this approach, you may still be able to use your tire again with just a fraction of the amount of purchasing a new one. However, tire patch costs can vary from the materials used to who will conduct the repair itself.

Do-It-Yourself tire patch repair will cost you around $6 since you’re just paying for the cost of materials. On the other hand, if you take it to the shop for a repair, you’ll run from $10-$40, which includes the material used, the costs of labor, and other charges.

You may decide to have it done yourself instead due to the upfront costs of a tire shop; however, before driving to the nearest dollar store to buy a tire patch, you should also determine if your damaged tire is still worthy of repair. You also have to identify if you can really patch it up yourself or hand the task over to an experienced mechanic.

Tire Patch Cost Break Down

The pricing set on tire patching in service shops varies in every shop. What is the same though is the composition of charges. These include the mechanic’s labor charges, the cost of the patching material itself, and other jobs that may be required prior to or after the tire patching.

Mechanic’s labor costs

Remember, you are paying the mechanic’s time he/she allotted to repair based on his or her expertise. The average labor rate for mechanics runs to about $100-120/hour. Let’s say a tire patch would take at least a quarter of an hour, that’s equivalent to $25-$30.

Costs of material

That $6 previously mentioned on the costs of tire patch were based on a retail average. Tire shops, on the other hand, purchase their materials in bulk to save on costs. What differs is their mark-up plus other materials like vulcanizing cement and/or sealant.

Other job orders aside from tire patching

A blown-out tire might need a rebalancing, so that’s another labor charge of about $10. For tasks like this apart from the patch for the puncture, confirm with your shop’s mechanic for other related repairs beforehand.

The cost of getting a tire patched comes greatly to the cost of the time your tire is handled by a mechanic. In other words, you are paying for their skill and not on the materials alone. You should also consider the investment of the equipment they used like the tire changer machine which extracts the tire from the wheel.

Is Your Tire Beyond Repair?

Since not all punctures are the same, not all of them are repairable. In order to determine if your tire can still be patched and work as intended, there are certain checks that your mechanic will undergo to verify the gravity of damage. These range from checking the distance of the puncture to the sidewall to checking the extent of damage to your tires.

Check if the puncture is close to the sidewall

How close? The puncture should not be as close as 2 inches from the sidewall. One easy way is to check with your thumb if it has some distance to the tire’s sidewall, it is still repairable, but if not, you shouldn’t continue with your DIY since tire shops will treat this case as beyond repair.

Why do tire shops consider this unrepairable? Don’t get the context wrong that a test will lead to quick bucks since you’ll be recommended to have a new tire. The condition behind this test is more about your safety while driving than profit.

The reason is that the patch won’t be able to hold the air pressure near or within the sidewall, and an eventual air leak is bound to happen. This can lead to serious blowouts which compromise the safety of everyone around you.

Check the extent of the puncture

Aside from the puncture’s position, its size also matters whether a repair is still possible.

The reason behind this is because patches are not intended to hold air over large surface areas.

Therefore, punctures should only be at least 2 and a half inches. A nail puncture, for example, can pierced tires typically as wide as its diameter, a hole this small is where a patch is still possible. However, if you’ve caught your tires with shards of glass, metal sheets, or hit a pothole very hard, chances are you’ll end up with a wider puncture which is beyond repair.

How Tire Patching is Done

The tire patching process can be deceivingly easy to pull off, especially if you have the material at hand. However, it can only be done in no time with proper and complete tools and equipment.

This task starts off with looking for the punctured area via different sensory checks and other techniques, detaching the tire from the wheel then cleaning the punctured area carefully before applying the patch.

Find where the leak is coming from

Mechanics often use their senses to locate where the leak is coming from. They start first by inflating the tires to gain considerable air pressure, this allows them to locate the leak easier as the air tends to escape in these leaks. They conduct checking it visually for any cuts, holes, or debris protruding from the tire. After that, they also check for any hissing sound.

Normally, they can already determine where the leak is coming from. In other cases, they also run their palm carefully around the tire to feel where the leak is coming from. Lastly, if there’s still the trouble of locating the leak, they use the ‘soap technique’ wherein a mixture of soap and water will be lathered around the tire, looking for any soap bubbling caused by air coming out of the leak.

The punctured tire will be removed

As the mechanic already determined where the leak is coming from, the wheel must be removed completely from the vehicle. After that, they’ll use a tire-changing machine to separate the tire from the wheel faster. In this process, they’ll also remove any object or debris that caused the puncture.

The tire will be patched

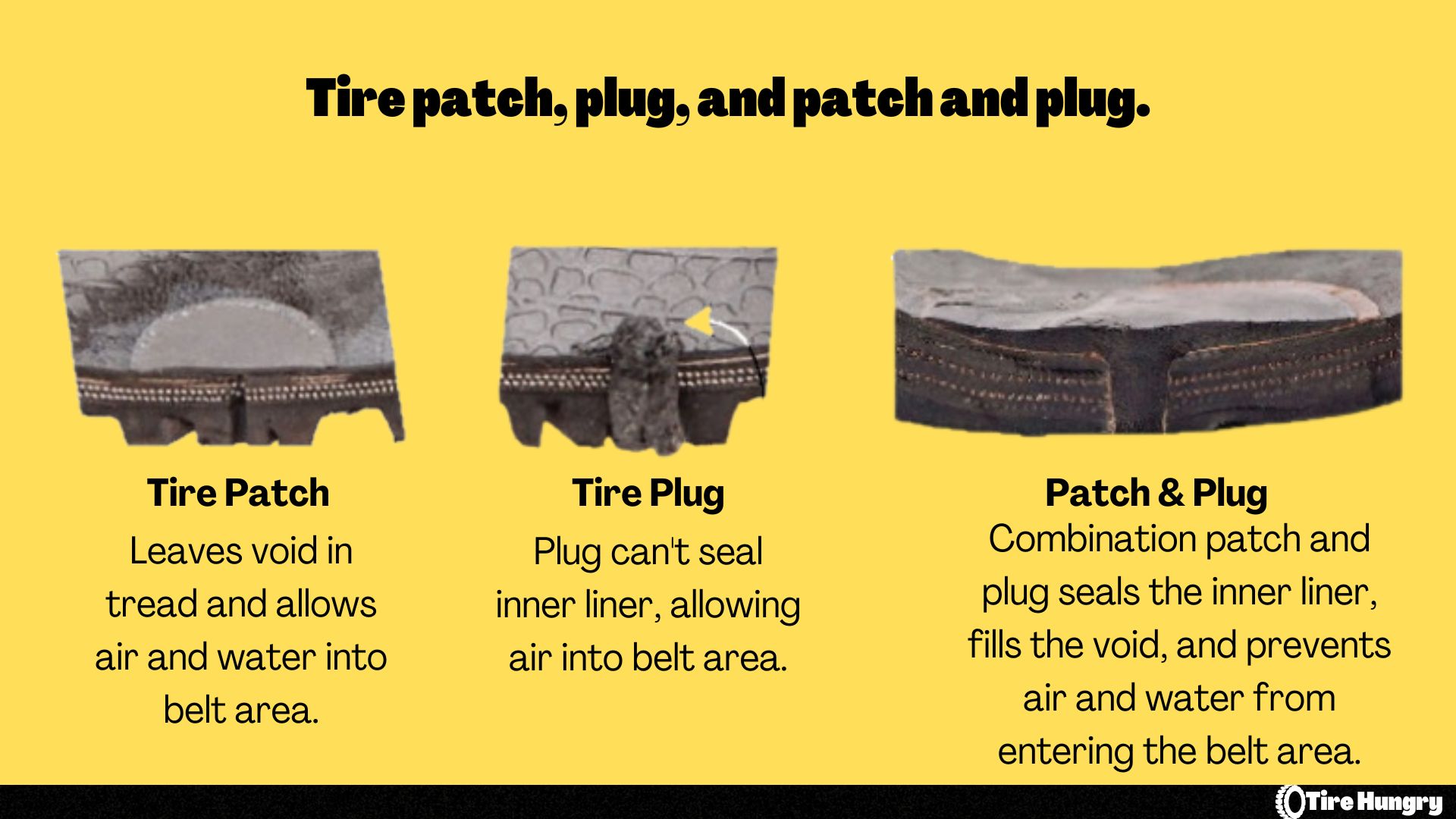

The punctured area must be cleaned and sanded off with a grinding stone or any sanding tool for the patch to adhere well on the tire, an air blow gun might be used to remove any remaining dust acquired from the buffing process. Then the patch, on its sticky side, will be applied to the interior side of the tire’s punctured area.

After the patch has been placed, a roller will be used to remove any air bubbles in-between the sticky side of the patch and the clean surface. An additional sealant will be applied to make sure no air will come out of the punctured area. The last thing in this process is to let the sealant dry for a while before mounting it again on the wheel.

The process will end by sliding the tire to the wheel using a tire-changing machine, then reinstalling it on the vehicle. There are instances that a rebalancing will be recommended by your mechanic.

Final Thoughts

Getting your tire patched, while usually a simple task, still requires proper tools, equipment, and time to locate the puncture, remove the tires, and apply the patch. With all the factors handed out, the average $10-$40 cost of tire patch process from tire shops is pretty justified. Be careful though, a good, and short research about the tire shop’s credentials will give you a prior idea if you’re just been ripped off.