Tires Internal Construction

Several components dictate a car’s performance. You have the engine, transmission, drivetrain, suspension, and plenty of other systems that enable a car to perform as the manufacturer intended. Nothing would be possible without the tires, regardless of how the other parts perform.

The rubber shoes on our four-wheeled friends are one of the most critical aspects for multiple reasons. Not only do they roll to provide grip and traction, but they deal with handling, braking, and overall refinement. You may think of them as just the rubber that rolls, but the tires take a lot of beating throughout their lifespan.

As much as we want, the roads aren’t always as smooth as a baby’s bottom, so there’s plenty of friction. You also have potholes, curbs, temperature differences, weight, and many other things that affect the tires, but they still deliver, in most cases.

When you consider how tortured the tires are, you’re wondering how rubber can survive. Well, today I’ll explain that and talk about their internal construction.

A Quick History Lesson

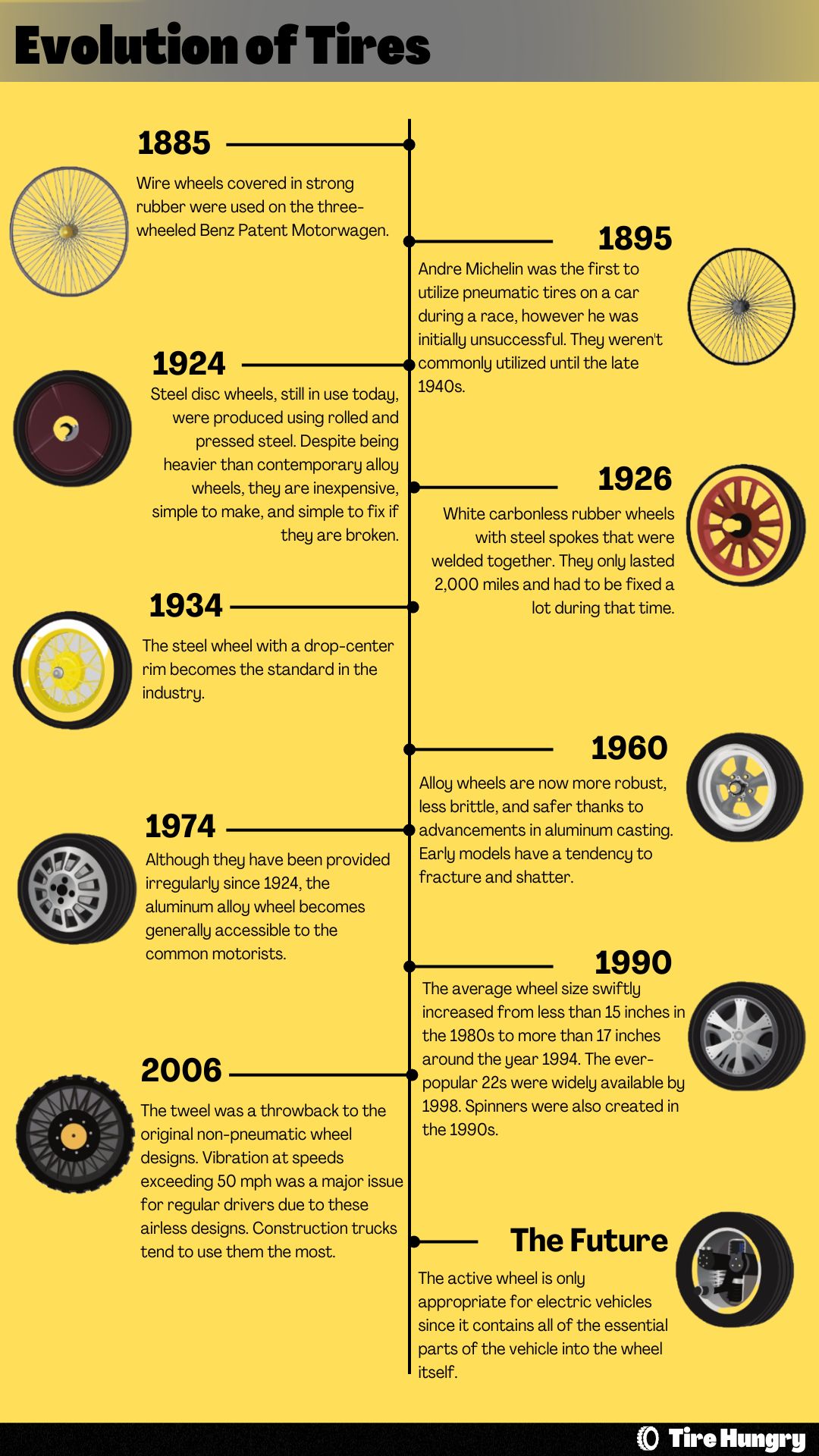

We’ve been using tires for a long time, and they aren’t something we’ve gotten recently. In the earlier days, they looked nothing like what we have today and were leather bands wrapped around metal or wooden wheels. As cars evolved, so did the tires, and the design and construction of today’s tires are far more advanced than in the olden days.

Today’s tires are a massive improvement over their ancestors. They are more durable and perform better, which is expected because today’s cars are also a massive leap over the ones from a century ago. The process of improving the tires results from using better materials and internal construction, which enables them to be as good as they are.

The general idea of internal construction hasn’t changed too much, but it has evolved. Today, we’ll discuss radial tires, the latest iteration of the iteration construction.

What are Radial Tires?

Radial tires were first introduced around the end of the 1940s as an idea that aimed to improve some drawbacks that the bias ply tires had. Better performance, durability, and in some situations, comfort is among the few advantages that radial tires have to offer. Even though these tires replaced bias ply ones in the 1970s, there are still some companies that make them, but they’re not for “regular” use. In most cases, you’ll find them in racing applications or a few that can be used in off-road conditions.

For construction, radial tires differ from bias-ply ones a lot. The cords of these tires are designed to be from bead to bead, forming a 90-degree angle with the rotation. Manufacturing tires with this design ensures that there isn’t any friction between the cords, like with the bias ply tires. The reduced friction between the cords ensures that heat isn’t an issue, prolonging the lifespan without a massive sacrifice on comfort.

The steel belts are the second thing that radial tires have, which is an improvement over the bias ply model. With this design, manufacturers aim to improve stability with the belts, whose task is to keep the tread as flat as possible. It increases the contact area, resulting in a tire that won’t wear down unevenly.

Advantages of Radial Tires

The entire idea behind radial tires is that they are better than bias-ply ones, so it’s natural for them to have many advantages. I went into some pros of these tires, but let’s look at all of the positive sides that radial tires bring to the table.

I’ll start with comfort. A radial tire is essentially a two-piece design with the cords running at a 90-degree angle to the rotational direction of the tire. If you look at only the cords, you can associate them with circular bands, meaning they’ll be flexible and soften up road imperfections. This design ensures the tire’s sidewall is more flexible, resulting in a softer ride. It is important to note that performance tires have stiff sidewalls by design. While a softer sidewall is good for comfort, it makes for a tire that won’t deliver the sportiest handling.

With bias ply tires, the layers are diagonal to the tire’s rotation, and each layer is at a certain angle to the one below. This may ensure strength, but as the tire rolls, there is friction between them, increasing heat, even if we’re talking about everyday driving. Radial tires solve this problem with the cord design. Since the tire is rolling forward, there isn’t any friction between the cords, even those under the tire taking all the weight.

The last advantage of the cord design is longevity. Heat is a tire’s worst friend, so since the radial tires aren’t generating heat as much as bias ply ones, you’re looking at a tire that would last longer.

Next up, let’s talk about steel belts and the advantages they bring. Radial tires implement steel belts to help improve stability, as these tires can handle being driven at higher speeds without risking any damage. The belts and cords work together to keep the tire from exploding.

Radial tires also have a few design improvements in the bead. The main one is to hold the tire safely on the wheel. To achieve this, manufacturers use wires, which are flexible enough to allow the tires to be installed on a rim but strong enough to keep them there firmly once the tire is inflated properly.

The overall design of radial tires ensures that these models have reduced rolling resistance. This is compared to bias ply tires, as even within the radial tire category, some have lower rolling resistance than others. As a result, you’d be getting better gas mileage when compared to bias-ply tires.

Disadvantages of Radial Tires

So far, I’ve been talking about the advantages of redial tires and their superiority when compared to bias ply, but as good as everything sounds, they’re not perfect and have some drawbacks. There aren’t many, but I have to mention them.

The first drawback I have to mention is the cost. Sure, radial tires offer more and are better, but the construction costs are higher, so naturally, they are more expensive. A direct comparison today is virtually impossible because bias-ply tires are rare and aren’t same in many aspects. When there was an overlap, radial tires were more expensive.

Next is the carrying capacity, but in situations when you neglect them. It sounds weird, and I’ll explain. Radial tires have a softer sidewall by design. While this offers a softer ride, it also means that the sidewall is prone to damage. A radial tire should be inflated as the manufacturer specified, and going too much under or over that will cause issues in the long run. The same goes for putting more weight and not inflating it properly, it will get squished, and the sidewall can get damaged.

Are there Bias Ply Tires Today?

Yes, but they’re very rare, and you’ll find them only for specific applications. For the most part, they still use bias ply tires in construction or other areas where heavier loads are carried. The stiffer sidewall construction enables them to be loaded without worrying about damaging the sidewall. With that said, there are some radial options with reinforced sidewalls that won’t have a problem with that, which is why both types are still used in this application.

Next up is off-roading, which is even rarer, and it’s the same reason as with construction – the sidewall. Some old-school off-roaders still use bias ply tires, but they are very rare, and not many manufacturers have them.

The low cost of bias ply tires is the main reason most trailer tires use that design today. You’re not driving at high speeds, and the trailer rarely does much except for dragging behind your car and truck. In these conditions, you should be fine with bias-ply tires as long as you maintain them as intended.

Finally, we have classic car owners who still rely on bias-ply tires. Many of the popular brands we often mention here still make these. Considering that some of these cars are from an era before World War 2, you won’t have any luck fitting a set of Pilot Sport 4S.

Conclusion

There isn’t much to talk about, but I’ll round things up. Radial tires are a far better option than bias-ply ones, despite having a few cons. They bring many improvements over their predecessor, so it’s natural to see them dominate the market with modern vehicles.

Sometimes bias ply tires are considered as a better option. These situations include construction, trailers, or vintage cars.

Generally, I recommend getting the type of tires your vehicle came with. You can experiment, but you won’t get the same performance and drivability.