Explaining the Parts of a Tire

Every car owner relies on tires to get whatever the car manufacturer promised. We can look at this from a performance perspective or safety, but at the end of the day, we have them to thank. No matter if you’re picking up the groceries or trashing your car on a track, the key element is the tires.

We often talk about their performance or durability, which is what most people are interested in. In some situations, we scratch the surface on some of the construction or design and how those translate into real-world performance.

With that said, some people want to know more about the tires in terms of construction. They are in luck because today I’ll be talking about the parts of a tire and how they work together to give you the performance you rely on.

What are the parts of a tire?

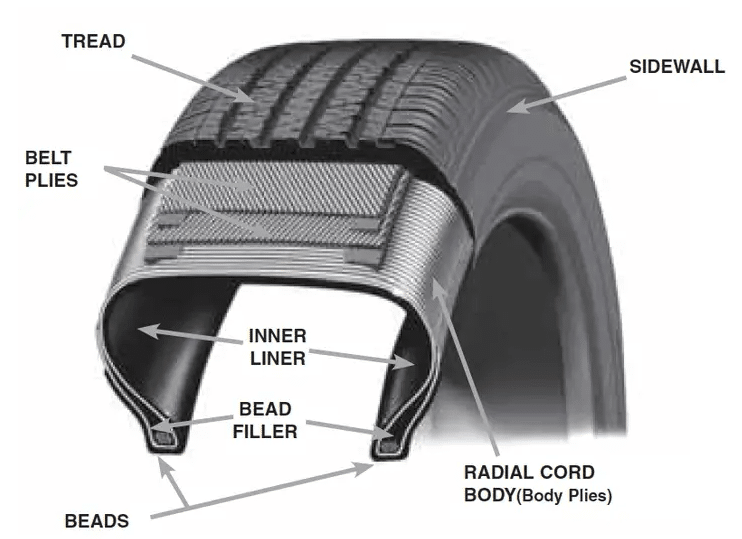

We look at the tires as a piece of rubber and don’t think too much of the other components. In this guide, I’ll break down all the aspects of a tire and explain their role in how they deliver performance or longevity.

Tread

Whenever we mention tread, we usually refer to the tread design, which is technically similar, but not the same. The simplest definition of tread is the part of the tire that’s in contact with the road. This is the portion that’s responsible for delivering grip and traction, braking, steering and everything else a tire does.

The tread has an enormous responsibility and, combined with other aspects of the tire, delivers the overall performance. Looking at the tread alone, it’s mainly for dry performance, wear, safety, fuel economy, those areas. As for the performance in other conditions, there are a few more parts that help.

Sipes

When you look at the tread design closely, you’ll see wavy cuts in the blocks. That’s not damage, those cuts are called sipes. The density of sipes will depend on the type of tire you’re looking at. Performance tires have fewer sipes because their main application is maximum grip and traction at all times. All-season or winter tires from other categories are the ones that will have more “cuts” on the tread blocks.

The main reason all-season and winter tires have more sipes is their application. Their primary goal is to offer traction in non-ideal situations. On a dry and hot road, the footprint is more than enough to deliver the performance. Damp roads or packed snow are two of the many areas where the sipes open up as the tire rolls and they work as claws to grab onto the surface and improve traction.

Grooves

The last part of the design of the tire is the grooves. They are like the sipes but are much wider and deeper. Depending on the design, you’ll have circumferential and lateral grooves, often referred to as channels. With V-shaped tires, they’re neither, but the goal of these is still the same. Regardless of the type, the idea behind the grooves is to channel the water beneath the tire.

Driving in heavy rain is problematic because at higher speeds you’ll experience aquaplaning. This is when the tire loses grip with the road and slides over the water. To combat this problem, tire manufacturers design the grooves that help the tire evacuate the water to ensure that the tire remains in contact with the road.

Shoulders

On the outer part of the tire’s tread are the shoulders. This is the thickest part of the tire and connects the tread with the sidewall, which I’ll talk about in a minute. Depending on the type of tire you’re looking at, the shoulder may have a similar design to the rest of the tread, or it may be different, like in off-road tires.

The goal of the shoulders is to connect the two sides of the tire and add support between them. Also, it’s very important in terms of drivability, especially when we’re looking at stability. The importance of the shoulder lies in the corner. Thanks to them, the tire can hold on to the road and remain stable in the corners.

Sidewall

The sidewall is the part of the tire that you can see from the side. A vertical piece of rubber around the wheels, which is the part that’s impossible to patch. I often mention the sidewall as an excellent place to get the information on the tire size, load index, speed rating and several others. With that said, the sidewall also plays a more important role.

With the information stamps aside, the sidewall holds the weight of the car. A tire inflated with the prepper pressure will have no problem carrying the weight and provide the performance. There is just enough flex in it to increase the contact patch and deliver higher levels of performance. It’s also the part that holds everything together in the corners. You may noticed me talk about sidewall flex in my reviews. This is a crucial thing because a tire with more flex won’t be as responsive and will be a lot softer with inputs. Another area the sidewall helps is with comfort. It’s designed to absorb the bumps and provide a softer ride.

You may have heard about sidewall reinforcements, which is a real thing. Mainly found with off-road tires, this reinforcement keeps the sidewall undamaged where you need to air down the tire. You can find something similar with high performance tires, where manufacturers are aiming for as little sidewall flex as possible.

Plies

With the exterior out of the way, let’s talk about the internal construction, starting with the plies. This is the most inner part of the tire that the overall construction relies on. The choice of materials will depend on the manufacturer or the type of tire, just as the orientation. Some tires have the plies running horizontally, while others have them running diagonally. This is the main different between radial and bias-ply tires.

Being the backbone of the tire, the plies play the most important role. They keep the tire’s shape as intended, while enabling the rest of the components to do their job. As you add pressure to the tire, the plies are holding everything together so that the shape remains optimal.

Belts

One layer above the plies are the belts. These go above and, unlike the plies, their advantage is from the outside. While the rubber keeps the internal construction safe, the belts add extra layer over the plies and offer a different kind of protection.

The belts reinforce the internal construction of the tire and work with the plies to maintain the shape. Besides that, with some tires, you’ll have additional reinforcements so that the tire can handle all the forces going through it.

Beads

A tire can perform as good as it can hold the air inside and to achieve that, it has the beads. These are made from steel wires usually reinforced with some kind of rubber and sit on a specially designed slot on the wheel. When mounted, the pressures push the beads to the wheel, which keeps the tire in place and enables it to hold the air.

As part of the bead design, there is also a little thing called bead filler. This is the lower portion of the sidewall aiming to provide additional support and reduce the flex under extreme cornering. You’ll find this filler in some performance tires.

Inner liner

The last part of a tire is the inner liner. This is the first layer of the tire that’s on the inner side of the tire. It’s made of rubber like most of the tire, but this is a different kind, designed not to let air pass through it. With the new tubeless tires, this is the part that’s closest to the inner inflatable tires of the olden era. Similar to how some bicycle tires work.

Most of the parts of the tire have multiple applications, but the inner liner has one. Its task is to hold the air in and maintain the pressure at the optimal level. If the tire is good, the loss of pressure over time will be as minimal as possible.

Conclusion

We often see tires as black pieces of rubber that go on our wheels, but the reality is much more complex. There are multiple parts that make up a tire, all of which work together to deliver the promised performance.

To be fair, there are slight variations from one tire to another, depending on the type. At the end of the day, the main components are the ones I outlined in this guide, hopefully answering the question you had.